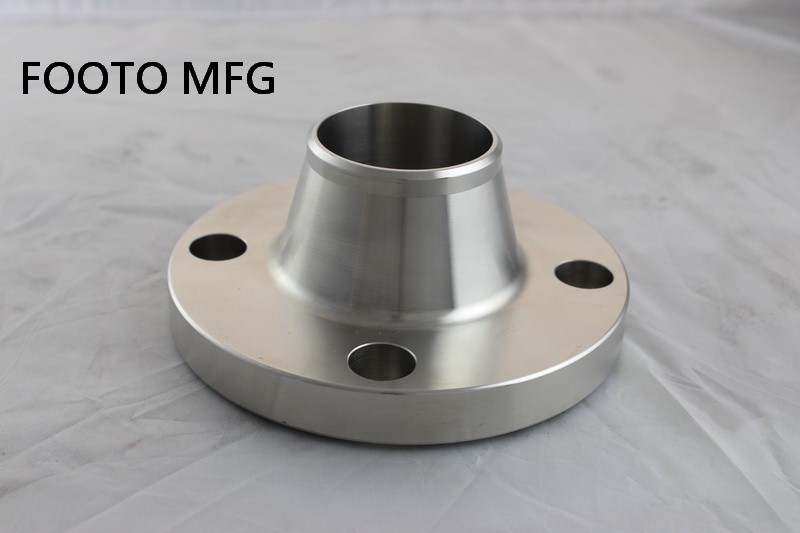

ASME B16.5 ASTM A234 WP5 WNRF Flange 2" SCH80 CL150

- Price

- US $18.8

- Model

- WNRF Flange 2" SCH80 CL150

- MOQ

- 1 piece

Review

Description

Product Specification

Size: 1/2”to 24”

Material: Stainless Steel,Carbon Steel,Alloy Steel,Alloy Steel,Duplex Stainless Steel and so on

Standard: ASME, DIN , EN, BS, ISO, JIS

Pressure: Class: 150,300,400,600,900,1500 and 2500 PN: 2.5,6,10,16,25,40,64 and 160,5K - 40K and so on

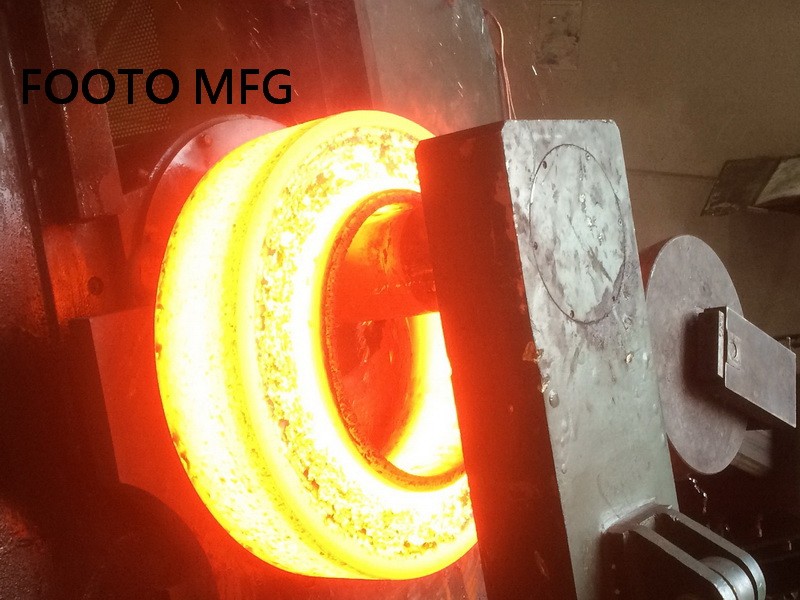

Production technique: Forged

Certificate: ISO9001-2015,BV,TUV,LR,etc.

Connect Type: Weld

Test: ---

Equipment: ---

Applications: Petroleum, chemical, power, gas, water, line pipe, heat exchanger,Ship building, construction, etc

Origin: Zhejiang, China

Packaging & Delivery

Packaging Details: Seaworthy plywood case or as customer requests

Delivery Detail: 5 - 10 days after receiving the deposit

Material

Stainless Steel: ASTM A403 WP304, 304L, 310, 316, 316L, 321, 347, 904L

Carbon Steel: ASTM A234 WPB, WPC ASTM A105 WPHY 42, 46, 52, 56, 60, 65, 70

Alloy Steel: ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91

Duplex Stainless Steel: ASTM F51, 2205, F53, 2507, etc

Other: According to your needs

Standard: ASTM, DIN, EN, BS, ISO, JIS , etc

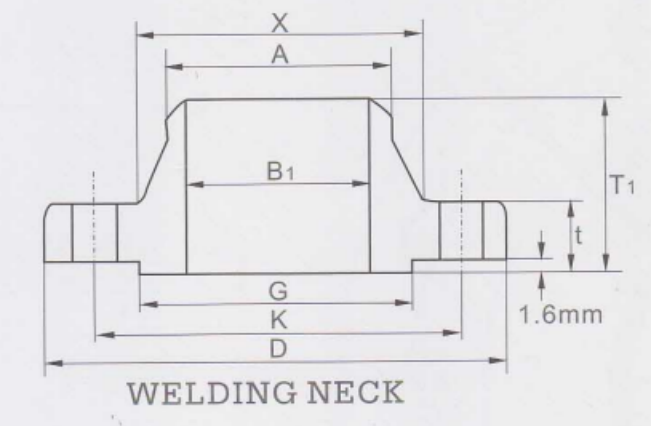

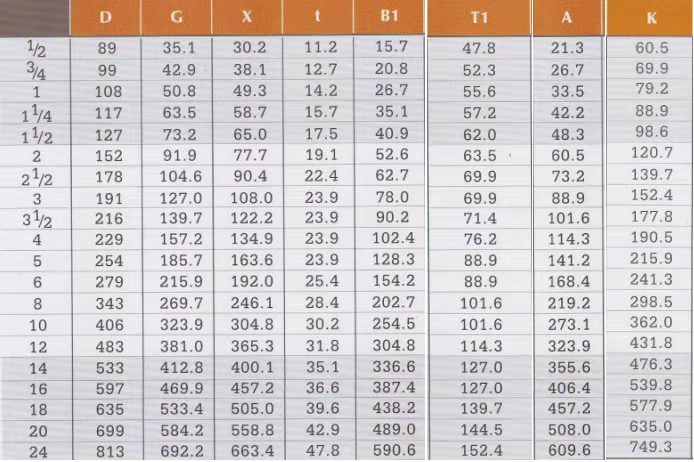

Flange Dimensions

What is weld neck flanges?

The Welding Neck Flanges (WNRF) are often used for high-pressure applications. To order a weld neck flange, it is important to specify the pipe is being used for. This is because the inside diameter of the flange will match the inside diameter of your pipe or Fitting. The buttweld joint this flange has with the pipe along with the tapered hub makes this flange very resistant to dishing and a sturdy connection. Weld Neck Flanges are ideal for extreme fluctuations of temperature and in environments where there may be a lot of bending and handling of the flanges.

Our Advantages

1. More than 20 years’ rich experience in manufacturing flange;

2.Strong technical force, fully equipment and steady development;

3.Perfect R&D, production, sales and after-sales service systems.

4.Good quality, fast delivery, promised stock notification in advance etc